High-pressure pumps play a critical role throughout the paper production process. From supplying water to the high-pressure showers to feeding trim squirts, these pumps ensure continuous and efficient operation for the highest quality paper production.

High-pressure showers are used to remove contaminants and improve the felt’s performance. They keep the wire mesh clean and hydrated for efficient paper production.

Trim squirts use high-pressure water to cut the edges of the wet paper web before it enters the press section. This process ensures a consistent sheet width throughout the production process.

Boiler feed water pumps maintain proper water levels and pressure within the steam boiler to ensure continuous and efficient steam generation.

What is imperative to the paper mill operator?

- Pump reliability

- Consistent flow and pressure

- Efficient water and energy consumption

- Easy maintenance

How do Sunflo pumps satisfy these requirements?

Sunflo pumps are integrally geared centrifugal pumps that deliver pulsation-free high pressure at low to moderate flow. The single stage, high speed design results in a small, skid mounted unit that is perfect for space-constrained installations near the paper machine.

Pump reliability

- Multiple flush plans reduce particulate build up at single seal for longer seal life

- Close coupled design eliminates alignment concerns between motor and pump

- Open clearances between the impeller and the casing help tolerate poor water quality

- No utility required outside of power to the motor

- Corrosion-free 316 stainless steel construction of the hydraulic components

- Heavy duty hydrodynamic thrust bearing handles 100% thrust loads from suction transients in the boiler feed water application

- Pre-warming of the pump is not required in the boiler feed water application

Consistent flow and pressure

- Multistage performance achieved with a high-speed single stage

- No tight wear tolerances mean no performance degradation over time

- Cavitation-free with Sundyne advanced inducer technology for low NPSH available situations

Efficient water and energy consumption

- Sunflo is sized and controlled to operate at the pump’s Best Efficiency Point to optimize energy consumption and component life

- Compact design allows for versatile options for installation locations, including close to the paper machine to reduce pressure losses

Easy maintenance

- Field replaceable shaft assembly for quick replacement and minimum downtime

- Minimum parts while providing multistage performance in a single stage pump

- Discharge orientation can be rotated every 90 degrees for ease of installation

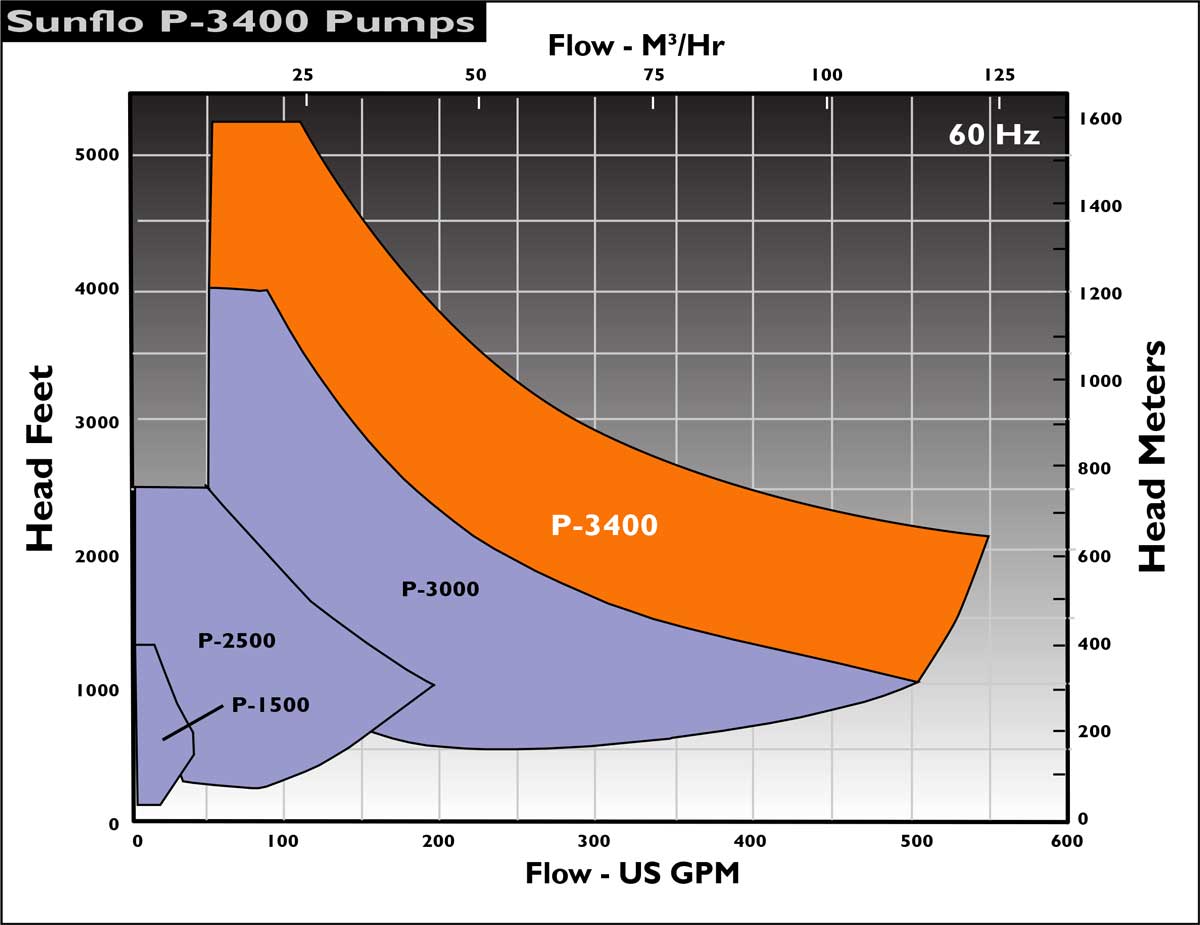

Performance Data:

| Capacity: up to 550 gpm (125 m3/h) |

| Head: up to 5,500 ft (1,700 m) |

| Temperature: up to 350°F (177°C) |

| Speed: up to 21,000 rpm |

| Frequency: 50/60Hz |

| Inverter Ready |

Materials of Construction

| Process Side: 316 Stainless Steel |

| Gearbox: Aluminum |

| Gears and Shaft: Steel per Agma Rating |

| Seal Plans: Plan 11, 13, 21, 23, or 53/54 |

| Seal Material: Carbon, Silicon Carbide, Metalized Carbon |