We have better performance with Sundyne in our power plant.

Pumps and compressors designed specifically for reliable power plant operation.

The power generation market includes all activities concerned with the creation and transmission of electricity to consumers, as well as corporate concerns who manufacture consumables, chemicals, metals and other high technology devices. Many industrial facilities, including refineries, chemical plants and steel mills – as well as hospitals, universities and other large public institutions – operate their own on-site power plants to generate electricity reliably and cost effectively. The vast majority of electricity in the modern era is generated via the use of steam-driven turbines, which are fueled by burning natural gas, coal or other fossil fuels. Growth in renewable energy sources and combined cycle gas turbine units are reducing the use of traditional power sources, creating opportunities for fuel gas boost compressors. Sundyne manufactures products that are an ideal fit for handling the applications and services associated with the power generation process.

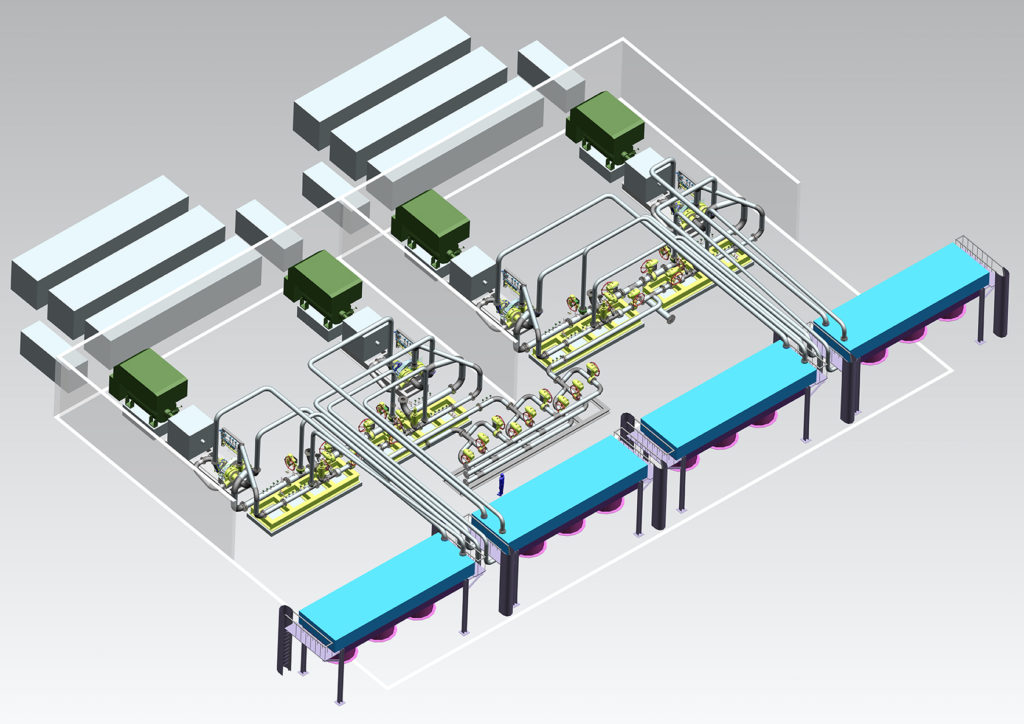

Fuel Gas Boost Compressors

Co-gen power plants require gas pressures in the range of 250-750 psig to operate their turbines in an optimal fashion. Interstate gas pipelines transport gas at different pressures – ranging anywhere from 30 to 125 psig. In order to boost incoming gas pressures to levels required by turbines, many plants deploy fuel gas boosters. Sundyne integrally geared compressors minimize downtime for 24 hour a day combined cycle power plant operation.

Water Injection Pumps

Commercial power generation plant operators utilize integrally geared pumps to inject demineralized water into the combustor through the fuel nozzles to regulate the combustor flame temperature and lower NOx emissions. Operators also use reliable Sundyne pumps to cool down the intake air of the gas turbines to augment power output and improve the energy efficiency especially in hot climates with peak-demand periods.

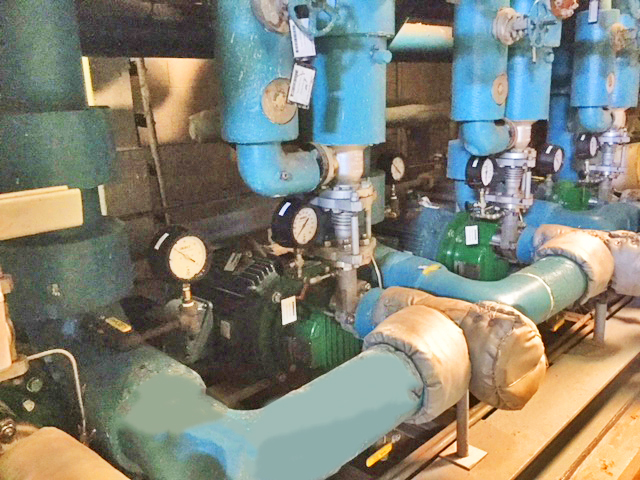

Boiler Feed Water

Reliable integrally geared pumps for combined cycle, combustion turbine, or Rankine cycle applications. Industrial grade Sunflo pumps are specifically designed to generate sufficient pressure needed to overcome the steam pressure developed by boilers, making them ideally suited to transfer feed-water into steam drums, and back from condensers, in closed loop cycles.

Condensate Return

Sunflo and Sundyne integrally geared pumps are widely utilized to move condensate throughout the power generation heat exchanging system with the ability to safely and efficiently handle high pressure and temperature in space saving designs with low maintenance. Increasing condensate return to the boiler improves efficiency of the power plant.