Conversions and Rerates of your Sundyne Pump or Compressor to increase MTBF – Mean Time Between Repairs

Sundyne has dedicated engineering and Aftermarket resources to identify pumps and compressors that aren’t meeting reliability expectations. Sundyne will upgrade equipment through reliability based conversions or re-rates.

Reliability Conversions are available for all Sundyne units, including Marelli and HMD. Process engineers will directly benefit from rerates and conversions by assessing reliability, maintenance and identifying process goals. Sundyne pumps and compressors that operate over 20,000 RPM, and older models will generally benefit from a rerate or conversion.

Key Benefits of Sundyne Reliability Based Conversions/Rerates:

- Maximize customer production – quick, cost effective way to get the most out of their process.

- Lower total lifecycle costs – reduced maintenance intervals, improved uptime.

- A la carte quoting for any customer need – testing/certs, hardware requirements, etc.

- Cost effective solution compared to new unit.

- Customer budget – could come from maintenance budget rather than CAPEX.

- Quicker delivery than new unit – close to part lead-times rather than new unit.

- Expedite options available for an upcharge.

- All conversions/rerates come standard with most recent technology parts.

Common Symptoms of Reliability Based Conversion Candidates:

- Abnormally high parts consumption.

- Any unit not meeting site MTBF requirements.

- Unusually high vibration.

- Energy consumption.

- Units where the operators have a “work around” to make the unit work.

- Not meeting customer performance requirements (miss-sized, running off the curve).

- Repeated repairs.

- Complaints from customer on a specific unit.

- Known as bad actor to maintenance and reliability team or on bad actor list.

- Excessive seal leakage.

Increase your MTBF with a rerate or conversion.

Sundyne pumps and compressors are engineered to fit specific processes and operating conditions based on process conditions. As economic, investment, and political factors change, process engineers update processes to ensure optimal production levels. Updates may lead to a significant variance between the as-built specs to current operating conditions. Sundyne has dedicated engineering and Aftermarket resources to convert pumps and compressors to optimized BEP for the process conditions.

Key Benefits of Sundyne Process Condition Change Conversions:

- Maximize customer production – quick, cost effective way to get the most out of their process.

- Optimize customer process – improve reliability and efficiency by properly sizing the unit.

- Engineered solution optimize machine to new process conditions.

- Customer budget – could come from maintenance budget rather than CAPEX.

- Quicker delivery than new unit.

- All conversions/rerates come standard with upgraded component parts.

Process engineers see immediate results:

- Needs based assessment with reliability, maintenance, and process engineers to understand what their goals are.

- Pumps and compressors not meeting site MTBF requirements may need to be re-sized based on changes to operating conditions.

- Review as built Sundyne specifications to current operating conditions to see if the pump or compressor is operating near BEP.

- Are you looking to debottleneck?

- Sundyne LMC-311P models in regen gas compression is a common process condition change conversion as process engineers either have too much Mole Sieve in their beds or want more throughput.

- Process engineers needing to run 2 units in parallel to achieve required flow – could convert to one properly sized pump or compressor with a standby unit.

- Install base – is there a Sundyne pump or compressor limiting output?

Many Sundyne pumps run with single seal arrangements while carrying dangerous fluids. These seal arrangements can lead to increased insurance premiums or compliance issues with emissions and environment regulations. Sundyne offers simple and affordable seal conversions that help reduce site emissions levels, improve environmental safety, and reduce insurance premiums.

Key Benefits of Seal Arrangement Conversions:

- Reduced insurance premiums.

- Reduced emissions levels.

- Improved environmental safety.

- Affordable solution – limited number of parts needed to convert to double or tandem seal arrangement.

- Wide variety of seal configurations available with updated data sheets and documentation.

Identifying Seal Arrangement Conversion Opportunities:

- All Sundyne pumps or compressors with single seal arrangements should be targeted –all LMV-80X and LMX/BMX-3XX models.

- Plant sites without a seal alliance.

- Single seal arrangements currently in operation.

- Local regulations/EH&S requirements drive update/convert machines.

- Increased insurance premiums from single seal arrangements.

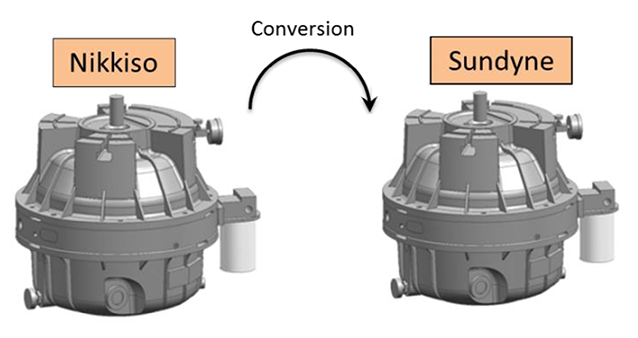

There are many older Nikkiso made Sundyne pumps and compressors currently in operation. These products do not include the newest technology parts that have been developed to improve reliability, efficiency, and operational performance. To ensure all Sundyne units are operating at peak performance, Sundyne has developed a Nikkiso Conversion program, which offers customers a simple and cost-effective way to upgrade their Nikkiso machine to a Sundyne specification unit.

Key Benefits of the Nikkiso to Arvada Conversion:

- The new gearbox has original factory specifications, the latest generation parts, and a new warranty – returns older model gearboxes to as new conditions.

- Improved lead-times with Sundyne made components – lead-times for Nikkiso parts are significantly longer than Sundyne parts.

- Sundyne made parts are more cost effective than Nikkiso spare parts.

- Significant product improvements for Sundyne units compared to Nikkiso.

- Sundyne engineered solutions available to meet same scope and supply as Nikkiso units.

- Field install capable on existing wet-end – no costly re-piping necessary.

- Complete Nikkiso unit can be replaced by new Sundyne unit without re-piping.

Key Technical Specifications:

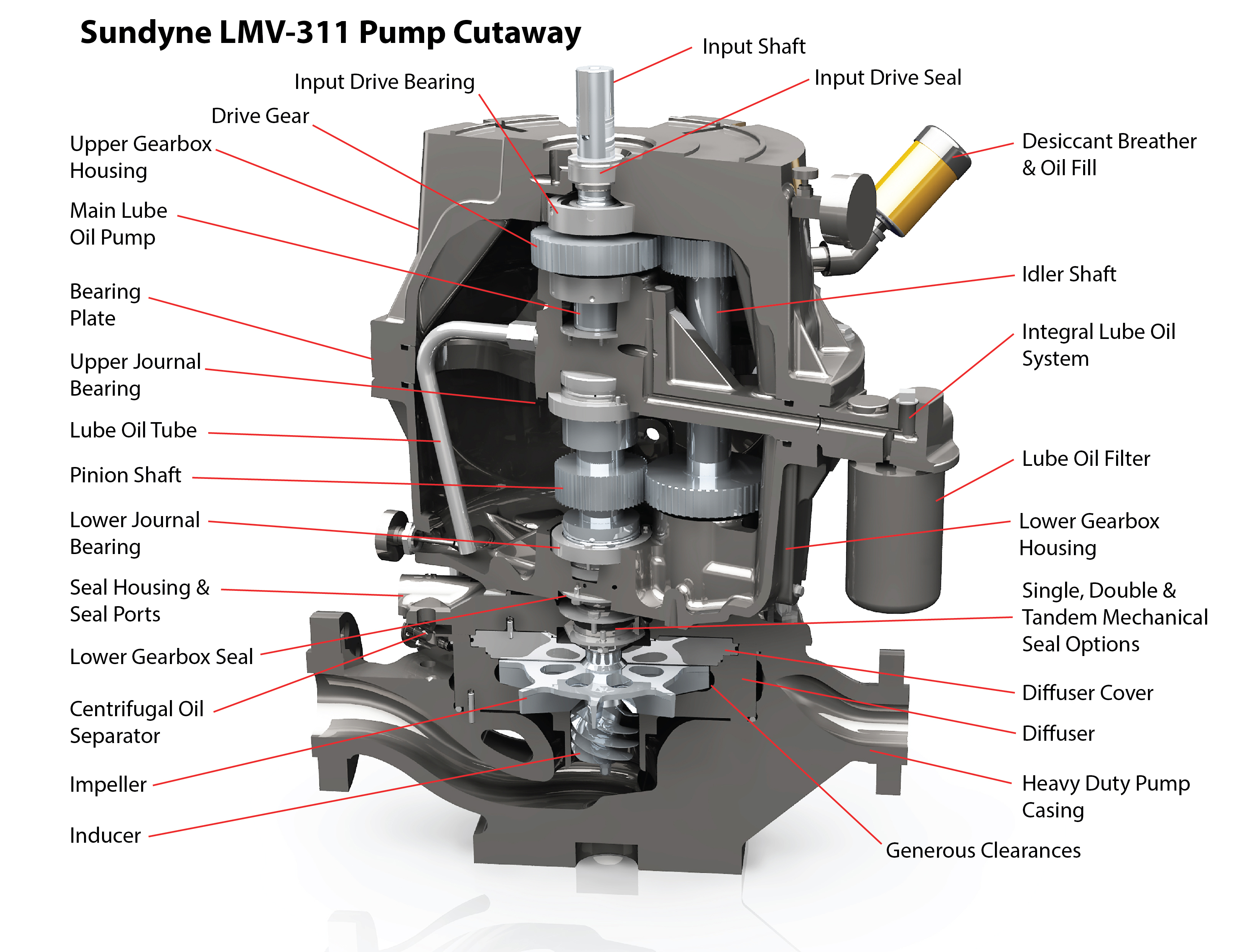

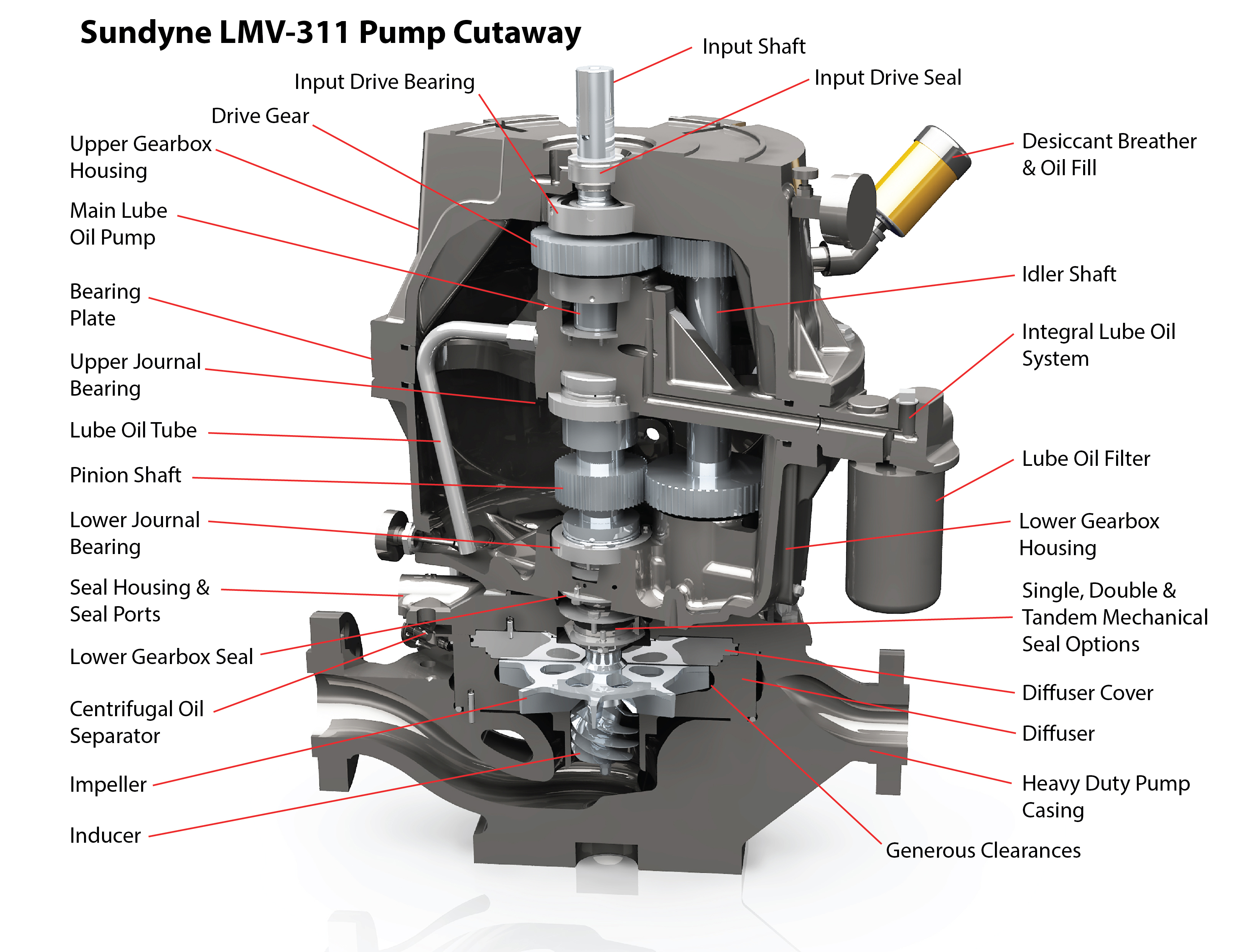

- Includes all the latest generation parts:

- Gearbox Output Seal

- Anti-Friction Bearings

- Oil Filter

- Desiccant Breather

- Precision Alignment Pin

- Extended Site Glass

- Anti-Rotation Plate

- Bearing Plate (LMV-31X only)

- Lube Oil Pump

- Gearbox Input Seal

- Gearbox Housing

Sundyne Genuine Parts Brochure, US – PDF

Sundyne Genuine Parts Brochure, A4 – PDF

Sundyne SundGARD Oil Filter, US – PDF

Sundyne SundGARD Oil Filter, A4 – PDF

Sundyne Gearbox Reliability Upgrade Kit Flyer, US – PDF

Sundyne Gearbox Reliability Upgrade Kit Flyer, A4 – PDF

Sundyne Gearbox Exchange Flyer, US English – PDF

Sundyne Gearbox Exchange Flyer, A4 English – PDF

Sundyne Gearbox Exchange Flyer, A4 Mandrin – PDF

Sundyne Gearbox Exchange Flyer, A4 Korean – PDF

Sundyne Gearbox Exchange Flyer, Deutsche – PDF

Sundyne Gearbox Exchange Flyer, Espanol – PDF

Sundyne Gearbox Exchange Flyer, Portuguese – PDF