A compact, vertical sealless magnetic drive pump for safe processing and handling of hazardous and valuable hydrocarbons and chemicals

The GSPV range of vertical pumps caters to a variety of applications such as booster packages, condensate transfer, hydrocarbon transfer and sampling packages. Its compact design particularly lends itself to offshore applications where space is at a premium.

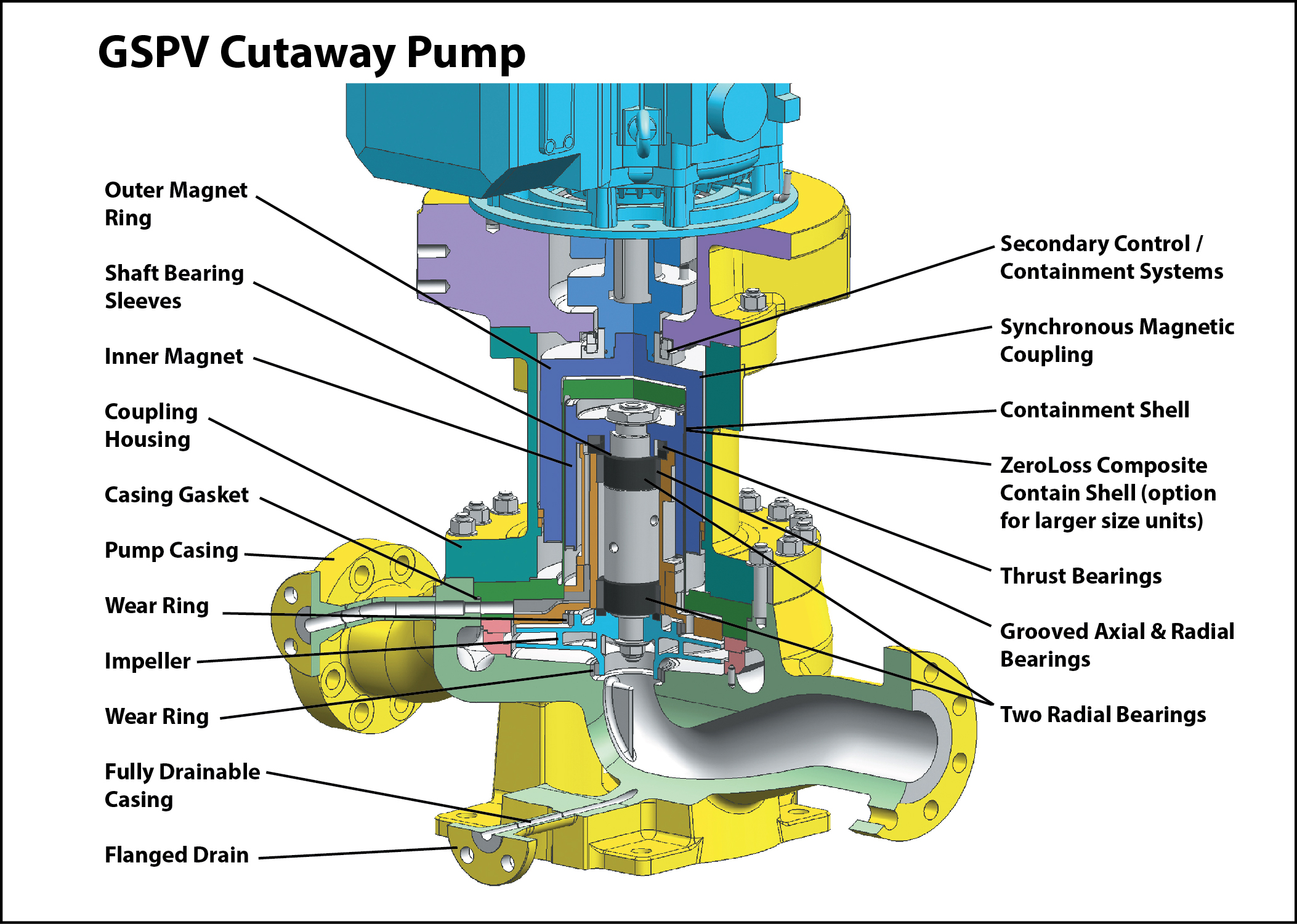

The use of fixed diffuser parts outboard of the impeller instead of a volute casing optimized the best efficiency point and allows variation of the head rise to shut-off for a range of duty points. Each hydraulic is offered with at least two diffuser options. The diffuser may be changed in situ, without removing the casing from the process, should pump duty change significantly.

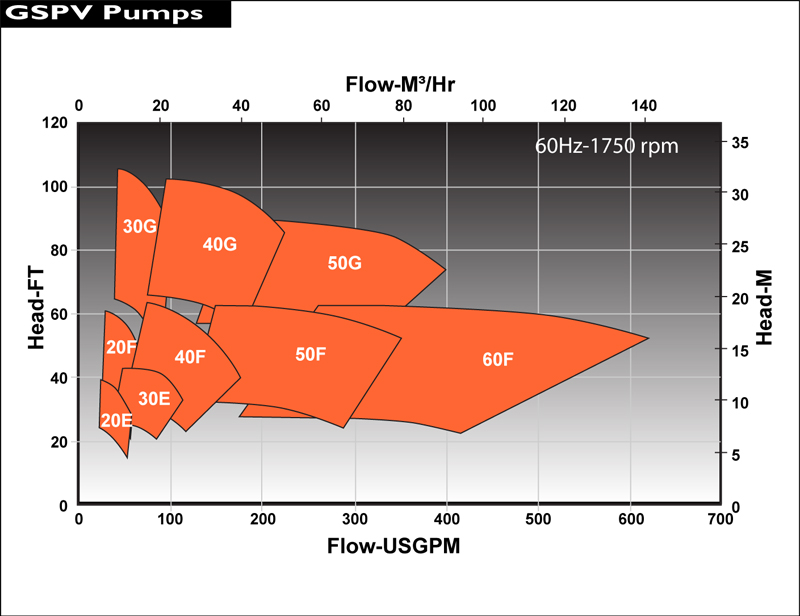

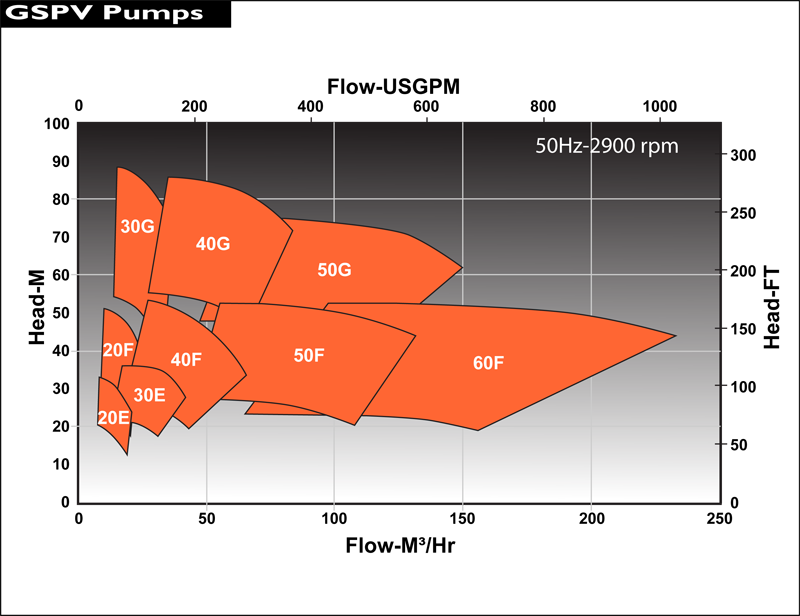

- Flows up to 1,250 GPM (285 m³/hr)

- Heads to 430 ft (130m)

- Temperature Range -40 to 400°F (-40 to 205°C)

A major advantage of having a diffuser is a significant reduction in radial loads and the consequential low vibration levels experienced and stabilization of the characteristic head curve.

The rigidly coupled vertically mounted design has nine hydraulics split between two frame (magnetic coupling) sizes to suit the power requirements, with the option of ZeroLoss shells in all configurations.

APPLICATIONS

Chemical Processing

- Chlor-Alkali

- Pesticides

- Insecticides

- Herbicides

- Fertilizer

Hydrocarbon Processing

- Sour water

- Sulfuric acid

- Benzene

- Xylene

- Toluene

Upstream

- Produced water

- LACT

Aquatic and Marine

- Seawater

- Caustic

Battery Manufacturing

- Sulfuric acid

- Potassium hydroxide

Biofuels

- Bio-diesel

- Ethanol

Food and Beverage

- Fragrances

Mining

- Sodium cyanide

- Sulfuric acid

- Hydrochloric acid

Pharmaceutical

- Silicon oil (Heat transfer fluid)

Pulp and Paper

- Chlorine

- Sulfuric Acid

Semiconductor Manufacturing

- Hydrofluoric acid

- Sulfuric acid

Steel Finishing, Pickling, Etching and Plating

- Hydrochloric acid

Water and Wastewater Treatment

- Sodium hypochlorite

- Sodium hydroxide

- Sulfuric acid

- Ferric Chloride

Our pumps combine cutting-edge technology with over seventy years of expertise and experience to give you complete peace of mind.

The vertically mounted GSPV pump provides all of the benefits of a magnetic drive sealless pump in a compact package. Requiring minimum floor space, the GSPV meets all of the requirements of API 685, making it ideal for chemical and petrochemical, oil and gas applications, including those where space is at a premium, such as in offshore installations. Dimensionally the range conforms to BS4082, thus providing a sealless upgrade solution to existing installations.

- Modular design based on established GS components

- Designed to retrofit existing sealed designs

- Diffuser design optimizes pump efficiency and curve shape

- Simple path for sealless upgrade

- ASME VIII compliant

US 60 Hz

- Heads to 1,146 ft

- Flows to 3,647 gpm

- Maximum Motor Power 535 HP

- Temperature Range -40 to 660°F

- Maximum Case Working Pressure 580 psi

- Hydrotest Pressure 870 psi

- Maximum Viscosity 200 centistokes

- Solids Range Maximum of 5% w/w less than 150 microns

- Motor Details Industry standard

- Mounting Configuration Horizontal close and long coupled

- Dimensional Standards API 610 OH2, ISO 13709

- Number of Available Hydraulics 28

- Available Flanges 150#/300# RF

Metric 50 Hz

- Heads to 245 m

- Flows to 3,467 m3/hr

- Maximum Motor Power 400 kW

- Temperature Range -40 to 350°C

- Maximum Case Working Pressure 19.3 kg/cm2

- Hydrotest Pressure 41 kg/cm2

- Maximum Viscosity 200 centistokes

- Solids Range Maximum of 5% w/w less than 150 microns

- Motor Details Industry Standard

- Mounting Configuration Horizontal close and long coupled

- Dimensional Standards ISO 13709

- Number of available hydraulics. 28

- Available Flanges 150#/300# RF

Standard materials of construction

- A-8 and S-5 with silicon carbide internal bearings and spiral wound gaskets.

Other material options are available on request

- Duplex Stainless Steel

- Alloy 20 and Alloy C276

- Various flange options are available as standard

POWER MONITOR

Installed in the Motor Control Center (MCC), a power monitor measures the power required to operate the pump. By setting High and Low trip points, the power monitor is the perfect solution for protecting your pump from:

- Dry running

- Low flow operation

- High flow operation

- Severe cavitation

- Magnet de-coupling

New ZeroLoss Containment Shell

Reduces Power Losses in the Pump to Zero

Excellent energy savings can now be made thanks to the introduction of the ZeroLoss containment shell for larger pumps. The elimination of eddy current losses can result in up to a 20% saving in power consumption, further enhancing the benefits and green credentials of magnetic drive technology from Sundyne HMD Kontro.

The advantage increases in proportion with the magnetic coupling size and is particularly appropriate for larger pumps, making the magnetic drive option even more attractive because through life costs are reduced further. Lower powerconsumption not only results in reduced running costs but alsopotentially provides lower initial capital costs, as smaller motors can be specified.

In addition, installation costs can be reduced as lower-rated cabling may be required, and there are space-savings from the ability to use a smaller base plate for the pump and motor combination.

SECONDARY CONTROL & CONTAINMENT

HMD Kontro Sealless magnetic drive pumps are available with secondary control devices to restrict any leaks. Mechanical devices are fitted to the drive shaft assembly and are activated in the unlikely event of containment shell failure. Also, the pump coupling housing is fitted with gaskets to eliminate any leaks across the joining faces.

Solids Handling

All HMD Kontro pumps, as standard, can handle up to 5% hardsolids and 150 microns diameter. The solid size can increase by fitting a self-cleaning in line filter, to 8% solids and 250 microns.

For larger solids HMD Kontro can provide pumps with a clean flush system or filter built into the flush pipework.

HMD Kontro GSPV Range Vertical Sealless Magnetic Drive Pump Brochure A4 – PDF

HMD Kontro GSPV Data Sheet US – PDF

HMD Kontro GSPV Data Sheet A4 – PDF

HMD Kontro Zero Loss Containment Shroud Technical Paper – PDF

HMD Kontro Zero Loss Containment Shell Brochure A4 – PDF

HMD Kontro Zero Loss Containment Shell Technical Profile A4 – PDF

HMD Kontro Zero Loss Containment Shell Data Sheet US – Â PDF

HMD Kontro Sealed vs Sealless Pump Technical Article – PDF

HMD Kontro Sealless Pump Know How Guide US – PDF

HMD Kontro Sealless Pump Know How Guide A4 – PDF

HMD Kontro No Seal Required Technical Article – PDF

HMD Kontro Product Range Brochure US – PDF