IGV's Boost Efficiency and Reduce Energy Costs

IGVs Maximize Operational Flexibility and Reduce Energy Costs

Sundyne centrifugal compressors are built to run for decades. Thousands of units deployed in the 1990s are still running today in refineries & petrochemical plants around the globe. Longevity is a function of design and maintenance – but even the best equipment can use an upgrade – especially in today’s CAPEX-averse environment, where plant operators need to get the most out of their equipment. One simple upgrade that will maximize operational flexibility, boost efficiency and reduce energy costs is the addition of Inlet Guide Vanes (IGVs) to legacy centrifugal compressors.

For assistance in upgrading your Sundyne Compressor, let us know about your situation.

________________________________________________________

Turbomachinery International Magazine Article

Centrifugal Compressor Upgrade, July/August, 2020

Sundyne “Fit for Purpose” Compressor Video

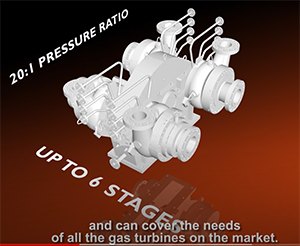

3:39 minute video outlining the benefits of Sundyne multi-stage compressors. March, 2020

Sundyne Centrifugal Process Gas Compressors: Engineered for Excellence

Sundyne Compressor Family Brochure, 2.5MB PDF