Sundyne to Showcase ANSIMAG and HMD Sealless Magnetic Drive Pumps at CHEM UK in Birmingham on May 21-22

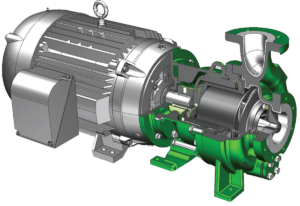

Arvada, Colorado: May 19, 2025 – Sundyne, a global leader in the design and manufacture of pumps and compressors, today announced an update to the ANSIMAG KF pump line with the release of the KF438F model.

Since 1985, more than 50,000 ANSIMAG pumps have been deployed around the globe in a wide range of applications, including Chlor-Alkali, isocyanates, plastics & polymers, battery manufacturing, agro-chemicals, steel and a wide range of water & wastewater applications. ANSIMAG pumps are specifically designed to handle corrosive or acidic liquids. All ANSIMAG wetted parts are molded ETFE (Ethylene Tetrafluoro Ethylene) components. A patented, fully encapsulated magnetic drive hermetically seals the inner magnets to isolate them from process fluids and maintain magnet integrity for the life of the unit. An aramid firer reinforced containment shell delivers unprecedented reliability.

The new KF438F pump increases flow capacity (up to 1000 GPM & heads to 290 ft) and optimizes performance through a larger magnetic coupling with increased motor size capability (up to 100 hp @ 60Hz). This new update enhances convenience for operators, because interchangeability with other ANSIMAG KF pumps enables operators to stock fewer spare parts.

“The ANSIMAG KF438 has built a strong reputation for high performance and impressive flow,” said Sundyne’s Product Marketing Manager for Sealless Pumps, Wesley McMillen. “When it was initially built, Sundyne’s engineers designed this model to meet a specific need, and the original KF438 featured different magnets and bushings than other members of the ANSIMAG family. With this recent update, the KF438F model brings the popular KF438 pump in line with the other ANSIMAG pumps.”

As part of the ANSIMAG family, the KF438F also benefits from:

- An ETFE (ethylene tetrafluoro ethylene) lining

- The ability to safely manage a wide range of chemicals, including corrosives and solvents up to 250°F

- Enhanced energy-efficiency, with a non-metallic containment shell that generates no eddy currents, thus eliminating heat generation

- Ease of service – with only nine wetted individual parts, onsite service can be performed without removing the casing from the piping and with no special tools required.

On May 21-22, Sundyne will showcase its ANSIMAG ETFE-lined Sealless Magnetic Drive pumps at CHEM UK, which is the UK’s largest event supporting the Chemical Processing & Formulated Product Industries. Alongside channel partner Kinder-Janes, Sundyne products and technical experts will be at stand F40.

The ANSIMAG pump line complements the extensive HMD CSA/CSI line of metallic sealless mag drive pumps. HMD pumps support all ASME / ISO standards and feature various frame sizes to accommodate an even wider range of flow & pressure requirements at higher temperatures. The combination of HMD and ANSIMAG offers customers the widest range of reliable, sealless mag-drive options, in ETFE-lined or metallic materials of construction, to address any chemical processing application. All ANSIMAG and HMD pumps come with the worldwide backing of Sundyne’s global support network.

To learn more about ANSIMAG pumps, or to schedule a briefing with Sundyne’s Sealless Magnetic Drive pump experts at CHEM UK, contact Sundyne today.

XXX

About Sundyne:

Headquartered in Arvada, Colorado with operations and presence in Europe, the Middle East, India, Asia, Japan and China, Sundyne is a global manufacturer of precision-engineered, highly reliable, safe and efficient centrifugal pumps and compressors for use in chemical, petrochemical, hydrocarbon, hydrogen, carbon capture, renewable fuels, power generation and industrial applications. Sundyne is the world leader in delivering low-flow, high-head integrally geared centrifugal pumps and compressors, safe and leakage-free sealless magnetic drive centrifugal pumps and diaphragm compressors. Sundyne pumps and compressors are available in API, ANSI/ASME, ISO and other industry compliant designs. To learn more about the Sundyne family of precision-engineered pumps and compressors, please visit www.sundyne.com.