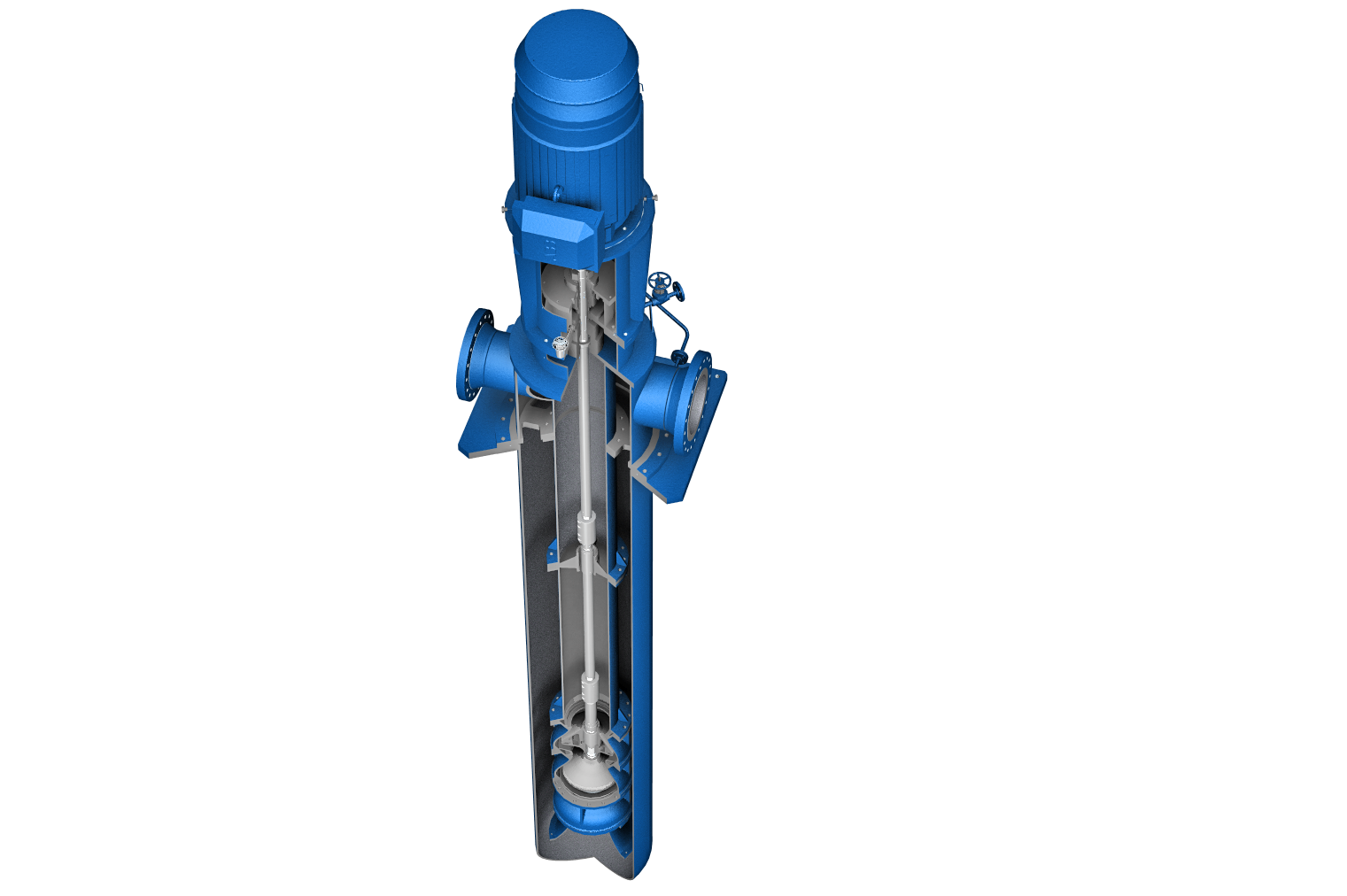

The VS6 Type ring section impeller is ideal for pumping fluids at medium and high pressures.

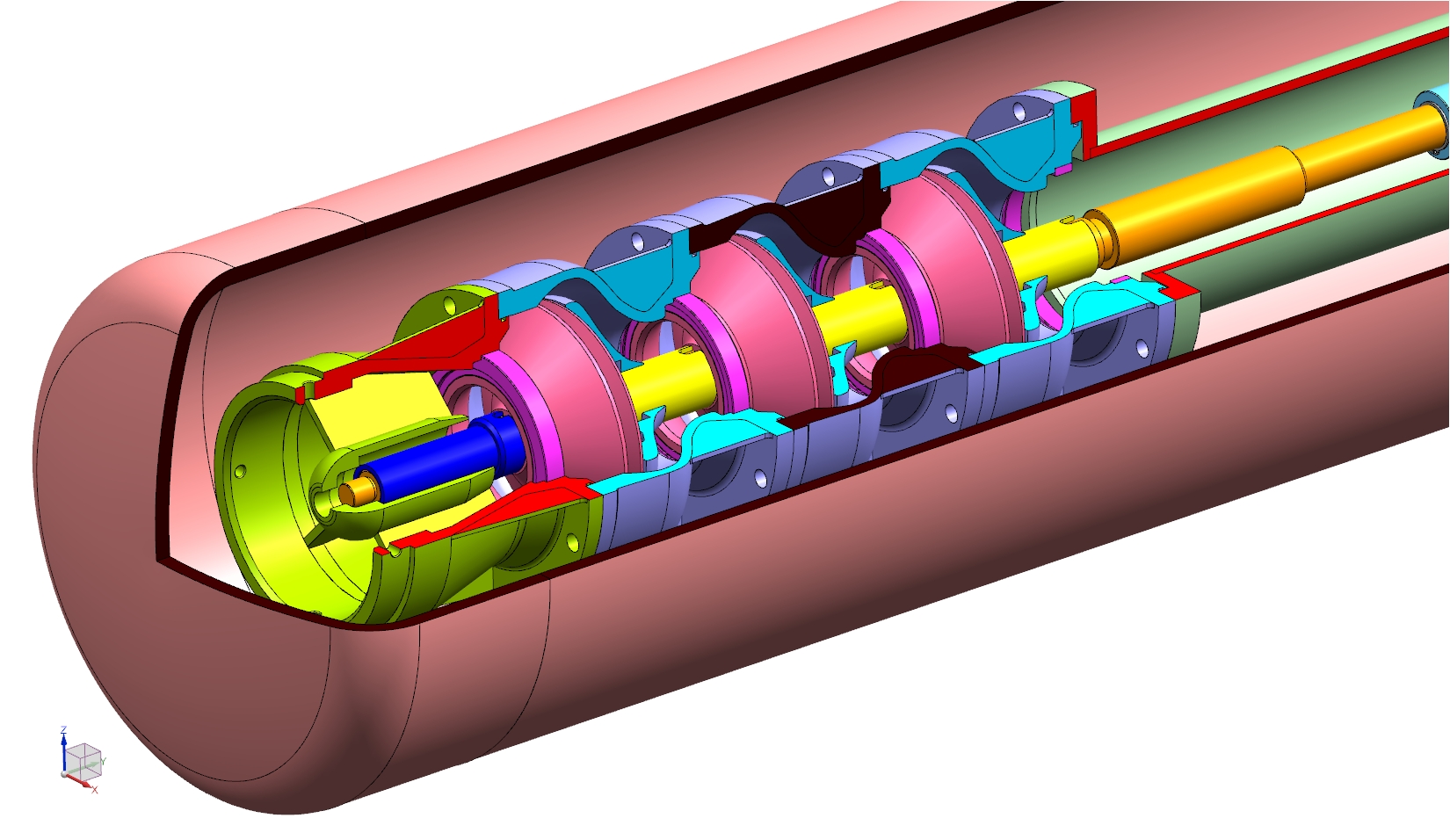

The FGB/TKVB pumps are ideal for pumping fluids at medium and high pressures. They are manufactured in materials selected for each particular application, all included within table H1 of the API 610 standard. Manufacturing processes guarantee the highest quality level and include rotor dynamic balance, hydrostatic and performances tests, measuring flow, head efficiency, NPSH, vibrations and the most rigorous quality control. Multistage centrifugal pumps up to 14 stages (standard construction), mounted in series separated and placed into perpendicular elements to the shaft rotation.

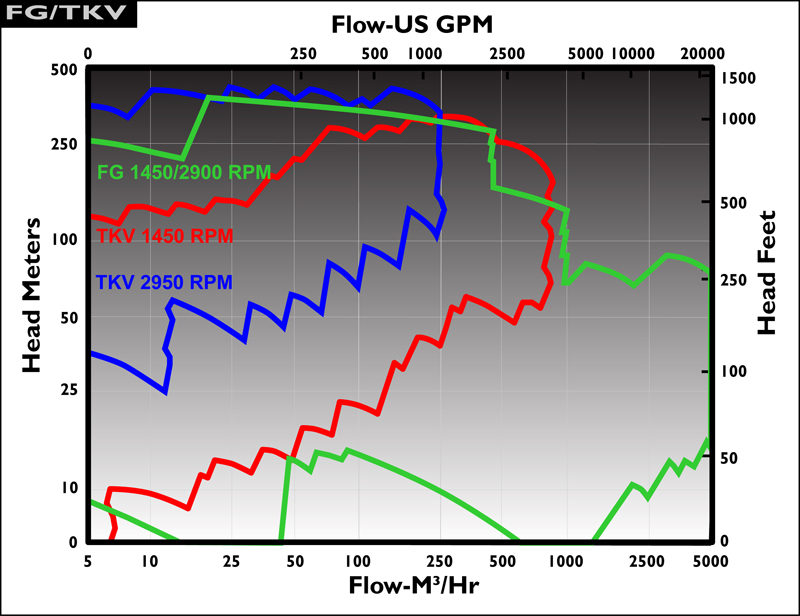

- Flows to 3,100 gpm (700 m³/hr)

- Heads to 1,200 ft (400 m)

- Maximum Working Pressure to 40 kg/cm2

- Temperature Range -125 to 482°F (-80 to 210°C)

APPLICATIONS

- Refineries

- Desalination plants

- Process charge

- API basins

- Condensate extraction

- Tank farms

- Tank fluid transfer

- Petrochemical plants

- Fertilizers

- Oil fields and terminals

- Off-shore and on-shore installations

- Reverse osmosis

- Synfuels

- Paper mills

- Other intensive high-pressure services

Proven to be reliable, efficient and long-lasting, Marelli VS6 pumps provide a number of operational benefits for process engineers and plant operators:

- API-682 mechanical seal or stuffing box options

- Flexible coupling

- Constant level oiler

- Thrust bearing

- Suitable with 60 Hz and 50 kW motors

- Suction flange arranged horizontally towards left hand side

- Discharge flange radially upwards from coupling side

- Ring section impellers with wear rings

US 60 Hz

- Heads to 1,150 ft

- Flows to 13,209 gpm

- Standards API 610 VS6

- Maximum Motor Power 1,341 HP

- Temperature Range -22 to 482°F

- Maximum Case Working Pressure 189 psi

- Maximum Suction Pressure Flooded

- Differential Head 656 ft

- Maximum Viscosity Consult factory

- Mounting Configuration Submersible vertical

- Seal Configurations API 682

Metric 50 Hz

- Heads to 350 m

- Flows to 3,000 m3/hr

- Standards ISO 13709

- Maximum Motor Power 1,000 kW

- Temperature Range -22 to 250°C

- Maximum Case Working Pressure 13 bar

- Maximum Suction Pressure Flooded

- Differential Head 200 m

- Maximum Viscosity Consult factory

- Mounting Configuration Submersible vertical

- Seal Configurations API 682

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||