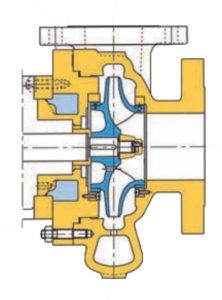

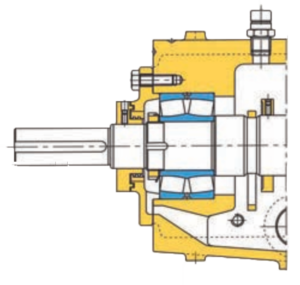

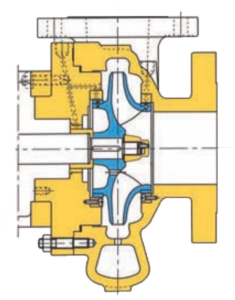

API-610 OH1 and ISO 13709 compliant for General Refinery Services centrifugal, single-stage, self-venting centrifugal process pump

The model ND is a single-stage, self venting centrifugal process pump for chemical, industrial, and petrochemical general services.

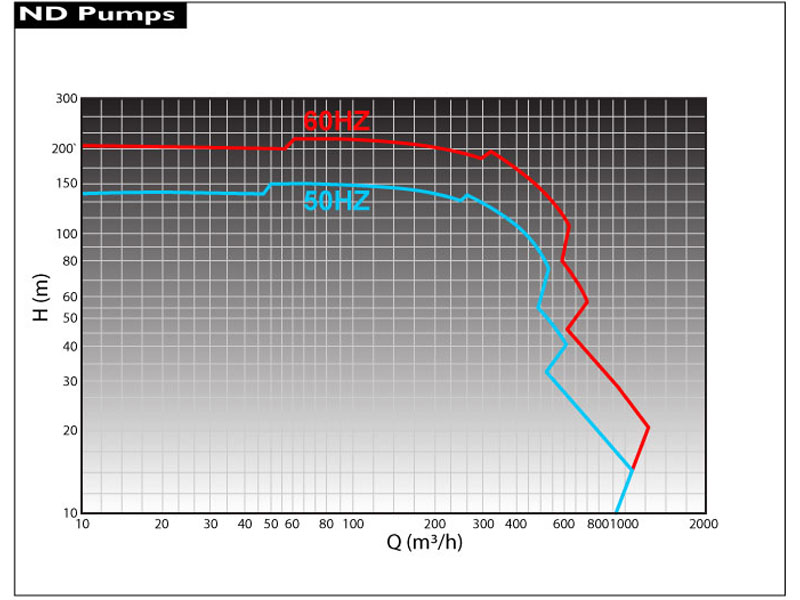

- Flows to 1,761 gpm (400 m³/hr)

- Heads to 492 ft (150 m)

- Temperature Range -58 to 482°F (-50 to 250°C)

Precision engineered API/ISO 13709 process pumps meeting rigorous engineering requirements for heavy duty applications while receding the total life cycle cost and improving mean time between repairs.

APPLICATIONS

Refineries

- Hydrocracking

- Topping

- Gas condensate

- HDS

- Merox LPG

- Amine

- Sour water

- Coking

- Platforming

Petrochemical

Crude oil and gas pipelines

Offshore and onshore oil and gas

Reverse osmosis

Synfuels

Proven to be reliable, efficient and long-lasting, Marelli OH1 pumps provide a number of operational benefits for process engineers and plant operators:

- API 610 11th Edition/ISO 13709 full compliance for reliability and accountability

- Suitable with 60 Hz and 50 kW motors

- Higher efficiencies due to a design with tangential discharge and a wide variety of hydraulics to match exact duty points

- Centerline mounted pump casing maintains alignment during operation and elevated temperatures

- Low suction specific speed and low NPSH characteristics with a wide choice of impellers for optimum efficiency over a large operating range

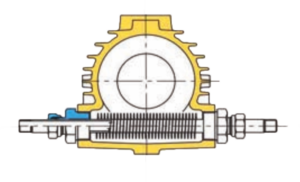

- Finned bearing housing to provide maximum heat dissipation under API 610 compliance

- Isolation chamber at bearing housing with a thermal barrier among mechanical seal chamber and bearing housing

- Deflection system with fins to improve cooling

- Labyrinth bearing seals to avoid external contamination and maximize seal and lubrication life

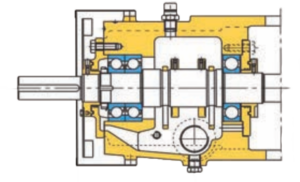

- Highly maintainable and replaceable wear rings to reduce overall life cycle costs

- Socket welded flanged drains and vents as standard (gussets and bracing also available)

- Choice of multiple impellers in each hydraulic pump casing for optimum efficiency over a wide operating range

- A variety of instrumentation options are available for monitoring all key operating perimeters (temperature, pressure, vibrations and more)

US 60 Hz

- Heads to 754 ft

- Flows to 5,283 gpm

- Standards API 610 OH1

- Maximum Motor Power 215 HP

- Temperature Range -58 to 482°F

- Maximum Case Working Pressure 232 psi

- Maximum Suction Pressure 145 psi

- Differential Head 492 ft

- Maximum Viscosity Consult Factory

- Mounting Configuration Horizontal-end top

- Seal Configurations Packing with optional mechanical seals

- Available Flanges PN17/FF

- Suction and Discharge Sizes Up to DN 200 / ND 150

Metric 50 Hz

- Heads to 161 m

- Flows to 960 m3/hr

- Standards ISO 13709

- Maximum Motor Power 160 kW

- Temperature Range -50 to 250°C

- Maximum Case Working Pressure 16 bar

- Maximum Suction Pressure 10 bar

- Differential Head 150 m

- Maximum Viscosity Consult factory

- Mounting Configuration Horizontal-end top

- Seal Configurations Packing with optional mechanical seals

- Available Flanges PN16/FF

- Suction and Discharge Sizes up to DN 200 / ND 150

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||

Customized High Temperature Features

Cooled mechanical seal chamber

External cooling for bearing housing with finned heat exchanger fed with inert fluid and/or water

Convection venting for bearing housing with a low noise fan placed at the rear in the coupling side

High Suction Pressure Options

Heavy duty bearing housings

Mechanical seals to meet safety and environmental requirements

Pump casing and seal chamber

Engineered bearings

Lubrication System

- Purge ports with drain valve

- Test gauges for condition analysis

- Oil mist lubrication system with purge ports

- Outboard oil mist system for assuring flow through each bearing

For Coking Services

- Backwash system for wear rings and neck bushing

- Specific coke crusher available

Baseplate Designs

- Pre-grouted and non-grouted for all driver types

- Special base designs to match oversize drivers, pump and turbines

- Tailor made baseplates available

- Skid mounting and oil field designs avaialable