Handle waste gas efficiently and safely

Flair, Vent and Re-injection

Sundyne integrally geared compressors generate high pressures and can safely handle contaminants without risk of exposure to the atmosphere, making them a perfect choice for handling waste-gas for flare, vent or re-injection.

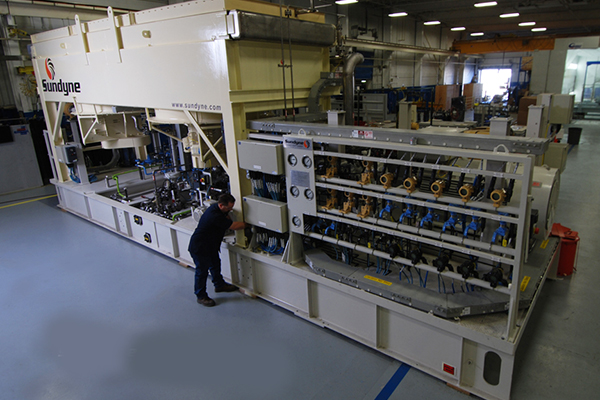

Sundyne Process Gas Compressors

Single- and multi-stage centrifugal designs meet API 617 standards applications for handling offshore injection, scrubbing, process gas, dehydration, regeneration, H2S removal, flare, vent and fuel gas applications. Each model is custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions. NACE compliant Sundyne compressors do not rust or corrode. Each unit is engineered in accordance with industry standards, and is designed to run continuously for 5 to 7 years without the need for costly maintenance or over-hauls.